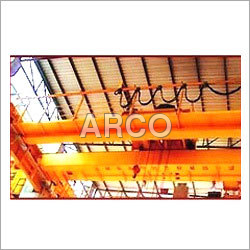

35T Double Girder EOT Overhead Crane

MOQ : 1 Number

35T Double Girder EOT Overhead Crane Specification

- Max Pressure of Hydraulic System

- N/A (Electrical crane)

- Max Oil Flow of Hydraulic System

- N/A (Electrical crane)

- Trolley Travel Speed

- 15 m/min

- Condition

- New

- Feature

- Other

- Working Presssure

- N/A (Electrical crane)

- Material

- High-grade steel

- Crane Type

- Other Cranes

- Application

- Material handling in warehouses and factories

- Control Type

- Remote control and cabin control

About 35T Double Girder EOT Overhead Crane

35T Double Girder EOT Overhead Crane

There are several ways that 35T double girder EOT overhead crane is changing the warehousing segment of numerous industries. With the proper safety regulations in place, this overhead crane is equipped with proper safety measures that allow workers to move heavy loads without risking their own lives. The hook and hoist on this crane allow it to lift and handle a wide variety of pallet racks with ease. The double girder EOT overhead crane can lift loads at different heights as well as various types of loads due to the immense flexibility of the hoisting mechanism and the stability of the twin girders.

Precision Material Handling

This double girder EOT overhead crane is expertly designed for precise and efficient lifting of heavy materials within warehouses and factories. Its advanced engineering and control systems maximize operational safety and productivity, making it an excellent solution for industries with high-demand material transport needs.

Powerful Performance and Sturdy Build

With a lifting capacity of 35 tons and constructed from high-grade steel, the crane is robust enough for a wide range of heavy-duty applications. Its powerful 15 kW system, combined with a heavy-duty design and efficient speed settings, offers reliable performance and longevity even in the most demanding conditions.

Versatile and User-Friendly Control

The crane comes with both remote and cabin control options, providing flexibility and convenience for operators. Safety features like limit switches and emergency stop ensure secure usage, while the 20-meter span caters to diverse facility sizes across manufacturing and storage sectors.

FAQs of 35T Double Girder EOT Overhead Crane:

Q: How is the 35T Double Girder EOT Overhead Crane operated?

A: This crane can be controlled using both remote control and cabin control, offering operators enhanced flexibility and accessibility. These options streamline processes and improve safety during operation.Q: What makes this crane suitable for heavy-duty material handling in factories?

A: The cranes high lifting and loading capacity of 35 tons, combined with its robust steel construction and efficient traveling and trolley speeds, allow it to excel in rigorous industrial environments where frequent, heavy lifting is required.Q: When should the emergency stop and limit switch be used?

A: The emergency stop should be used immediately in unsafe situations or equipment malfunctions to halt crane operation. Limit switches act as protective devices, preventing the crane or trolley from exceeding designated operating ranges during normal use.Q: Where can this crane be installed and utilized effectively?

A: It is ideal for large-scale warehouses, industrial facilities, and factories in India that require the safe and efficient movement of heavy materials over 20-meter spans and 12-meter lifts.Q: What is the process for installing and starting up this crane?

A: Installation should be performed by professional technicians or trained service providers. After assembly, routine safety checks are conducted before commissioning the crane for operational use. The included warranty provides additional peace of mind during initial operation.Q: What are the benefits of using high-grade steel in the cranes construction?

A: High-grade steel ensures excellent structural integrity, durability, and resistance to wear and tear, thus extending the cranes service life and maintaining reliable performance under heavy-duty workloads.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Double Girder E.O.T Cranes Category

Double Girder E.O.T Cranes

Price Range 25000.00 - 50000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless steel and Cast Iron

Crane Type : Bridge

Control Type : Remote Control

Color : Yellow

Double Girder Overhead Cranes

Price Range 25000.00 - 50000.00 INR

Minimum Order Quantity : 1 , , Number

Material : Metal

Crane Type : Bridge

Control Type : Remote Control

Color : Silver

Double Girder Overhead Crane

Price Range 25000.00 - 50000.00 INR / Unit

Minimum Order Quantity : 1 , , Unit

Material : Metal

Crane Type : Girder

Control Type : Remote Control

Color : Yellow

Double Girder Crane for Transformer Industry

Price Range 25000.00 - 50000.00 INR

Minimum Order Quantity : 1 , , Unit

Material : Metal

Crane Type : Tower Mounted

Control Type : Cabin

Color : Blue

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS