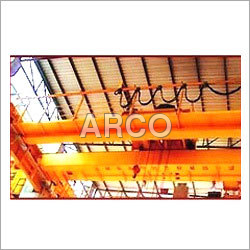

Double Girder Overhead Cranes

Double Girder Overhead Cranes Specification

- Recommend Power

- 220-380 Volt (V)

- Material

- Metal

- Crane Type

- Bridge

- Application

- Ship Building, Construction

- Height

- 12 Millimeter (mm)

- Product Type

- Overhead Cranes

- Span Length

- 5-25 Millimeter (mm)

- Loading Capacity

- 5-10 Tonne

- Color

- Silver

- Control Type

- Remote Control

- Limit Switch

- Yes

- Emergency Stop

- Yes

Double Girder Overhead Cranes Trade Information

- Minimum Order Quantity

- 1 , , Number

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 1 , , Number Per Week

- Delivery Time

- 3-4 Week

- Main Domestic Market

- All India

About Double Girder Overhead Cranes

Backed by rich experience in this domain, we are involved in manufacturing and supplying Double Girder Overhead Crane. These cranes are widely used in shipbuilding, nuclear, power, engineering and steel plants. Offered cranes are reckoned for their easy installation, accurate dimensions and durability. Owing to these features Double Girder Overhead Crane is highly demanded nationwide.

Other information:

Range: Double Girder and Single Girder EOT Cranes up to 100T capacity

We are the largest EOT crane manufacturers in India. We have comprehensive range of EOT heavy duty crane systems (double girder, single girder, underslung etc.) of capacity up to 100 tons for various applications in power, nuclear, shipbuilding, steel plant, heavy/general engineering sectors etc. We recommend you the perfect customised solutions after doing an in-depth analysis of your applications, production facility, factory, and material handling requirements.

Features

- Easy to install. Ensures maximum rigidity with a minimum dead weight

- Compact dimensions, low weight, easy to operate and maintain

- Safe and sustainable production at every level of our supply chain

- Product package also includes assistance with the installations, safety measures and training for operations and maintenance, as well as inspections and after sales services

- Precision flat helical / spur gear units in light alloy housings with case-hardened gears, high- grade surface treatment and permanent oil / grease lubrication

- Modular design, covering a very wide operating range. The systems are designed for ease of installation and maintenance and reliable operation, with fuse less circuitry, ducted wiring and non-screwed terminals. Each drive group is equipped with a motor overload protection

- Safe and reliable hoisting and travelling

- Higher efficiency to save power

- Micro speed for all motions through inverter (VVVF) drives with suitable interlocking

- Close loop circuit for hoisting mechanism with encoder feedback for fault detectio

- All motions are protected with limit switches to prevent over hoisting & over lowering of hook

- Platform with hand railing for easy, simple & safe maintenance of the crane extended partially or totally along the girder width

FAQs of Double Girder Overhead Cranes:

Q: How are Double Girder Overhead Cranes operated and controlled?

A: These cranes utilize remote control systems, allowing operators to manage lifting, lowering, and traveling functions from a safe distance, improving precision and safety on-site.Q: What are the notable safety features of these overhead cranes?

A: They come equipped with critical safety mechanisms such as emergency stop buttons and limit switches, which help prevent accidents by automatically halting operations in unsafe situations.Q: When is it advisable to use Double Girder Overhead Cranes in construction or shipbuilding?

A: These cranes are ideal for projects demanding substantial load capacity (5-10 tonnes) and stable movement across moderate spans, especially where continuous, heavy material handling is required.Q: Where can these cranes be installed or deployed?

A: Designed for indoor or covered environments, they are most commonly installed in shipyards, construction sites, and large manufacturing facilities that require heavy-duty lifting solutions.Q: What is the process for procuring and installing these cranes in India?

A: Clients can consult with certified fabricators, manufacturers, or suppliers. The process typically includes site assessment, customization of specifications, fabrication, delivery, and on-site installation with technical support.Q: How does the double girder design enhance crane performance?

A: The double girder structure distributes load more evenly and increases stability, enabling efficient movement of heavy materials while minimizing deflection and vibration.Q: What benefits does remote control operation provide in industrial lifting tasks?

A: Remote control improves operator safety by allowing distance from hazardous zones and facilitates precise handling, thus increasing overall efficiency and reducing the likelihood of mishandling heavy loads.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Double Girder E.O.T Cranes Category

Double Girder E.O.T Cranes

Price Range 25000.00 - 50000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless steel and Cast Iron

Control Type : Remote Control

Crane Type : Bridge

Feature : Hydraulic Crane

Double Girder Overhead Crane

Price Range 25000.00 - 50000.00 INR / Unit

Minimum Order Quantity : 1 , , Unit

Material : Metal

Control Type : Remote Control

Crane Type : Girder

Feature : Gantry Crane, Truck Crane

Double Girder Crane for Transformer Industry

Price Range 25000.00 - 50000.00 INR

Minimum Order Quantity : 1 , , Unit

Material : Metal

Control Type : Cabin

Crane Type : Tower Mounted

35T - Double Girder EOT Overhead Crane

Minimum Order Quantity : 1 Number

Material : Mild Steel

Control Type : Cabin

Crane Type : Girder

Feature : Hydraulic Crane, Portal Crane

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS